Inquire

jaw crusher shaft

PDF Crushing Plant--Jaw CrusherPDF

Crushing Plant--Jaw Crusher 1. This machine is used in mining, metallurgical industry, building material, highway, railway, and chemical industry. 2. It can crush mining stones and rocks whose compressive strength is not more than 320M Pa. 3. The max size of the stuff should not exceed the standard in the following table. 4.

Learn More

Jaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn More

Crushers - All crusher types for your reduction needs - Outotec

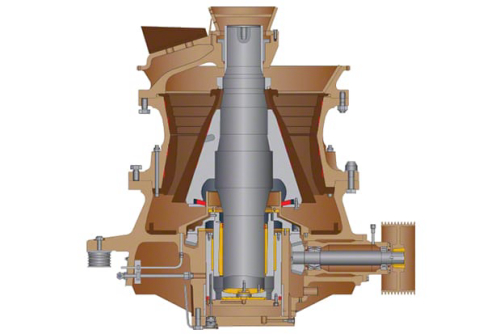

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Learn More

What Are the Differences Between The 7 Types of Crushers?

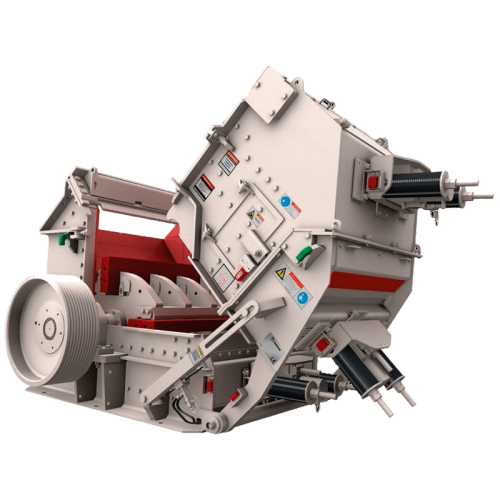

Jaw crusher needs to work together with feeding equipment to complement the crushing process. You can see that the granite material is reduced by the compressive force generated by two jaw dies. Horizontal shaft impact crusher crushing limestone. The mobile crushing equipment in Video is another type of HSI crusher, and it is very hot in

Learn More

1 Jaw Crusher Machine Manufacturer Indore - KV Metal Works

Established in the 1986, we, K. V. Metal Works brand Gold Crush, an ISO 18001 : 2007 Certified company for Quality Management System, are engaged in Manufacturing and Supplying superior quality Industrial Crusher and Vibrating Screen. Our product range includes Single Toggle Stone Crusher, Single Toggle Jaw Crusher, Double Toggle Oil based

Learn More

Jaw Crusher - Eastman Rock Crusher

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

Learn More

Jaw Crusher Shaft And Bearing Removal Technique

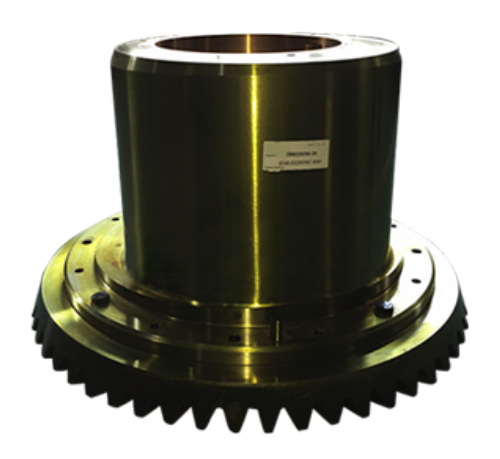

1.5.9 Jaw Crusher Eccentric Shaft Bearings: There are typically four Shaft and bearings Massive rigid eccentric shafts made from steel along with roller bearing European Type Jaw Crusher- Heavy Industry adjustment methods eccentric shaft is processed by forged mold. All of these make the JC series jaw crusher

Learn More

Cause Analysis and Problems Solving of Jaw Crusher

3The eccentric shaft tightening bushing is loose, causing no gap on both sides of the bearing housing of the frame,

Learn More

Jaw Crusher+eccentric Shaft+assembly

European jaw crusher for sale,mobile jaw crusher 50 ton per . Heightened movable jaw assembly lengthens life of JC jaw crushers.Movable jaw assembly, . Eccentric Shaft Rotation Speed (rpm) 320: 330: 330: 250:

Learn More

How jaw crusher works? - Sandrock Mining

3/18 · The jaw crusher crushes materials through the periodic movement of the movable jaw. The crushing method is driven and squeezed. The belt and pulley are driven by the motor, and the movable jaw does a fixed up and down reciprocating movement through the action of the eccentric shaft. When the movable jaw rises, the angle between the toggle plate

Learn More

Jaw Crushers | Crushing Equipment | Minyu Machinery Corp

2022/2/24 · With larger feed openings and bigger crushing strokes, the Minyu Jaw Crushers are suitable for crushing big size lumps in large quantity. They are especially recommended for primary and concrete recycling, river stones, tough ores, for a very long life. From the welded steel base to the rugged eccentric shaft, Minyu Jaw Crushers are built with

Learn More