Inquire

crusher size

Different Sizes Of Impact Crusher

Impact crusher,Impact breaker,Mobile impact crusher,Impact . Impact crusher is suitable for materials whose compressive strength is under 350Mpa, and particle size is less than 500mm.

Learn More

Impact Jaw Crusher Market Size In 2022 - MarketWatch

The global Impact Jaw Crusher market size is projected to reach USD million by 2026, from USD million in , at a CAGR of % during 2021-2026. Global Impact Jaw Crusher Scope and Market Size.

Learn More

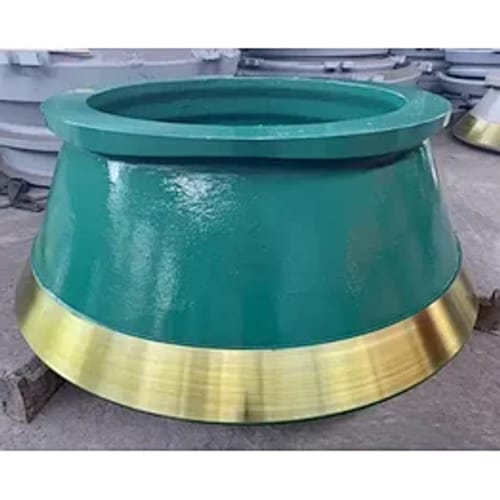

Cone crusher basics in 4 minutes — SRP

It’s hard to overstate the importance of feed size in a cone crusher. It is vital that you know, as accurately as you can, the size distribution of the raw material. The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher.

Learn More

Hammer Crusher Size | Crusher Mills, Cone Crusher, Jaw Crushers

Hammer crusher,Hammer breaker,Hammer mill crusher,hammer grinder. The Advantages and Disadvantages of Hammer Crusher . Advantages: 1. Big crushing ratio: Maximum feeding

Learn More

Jaw Crusher Explained - saVRee

Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws. For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width.

Learn More

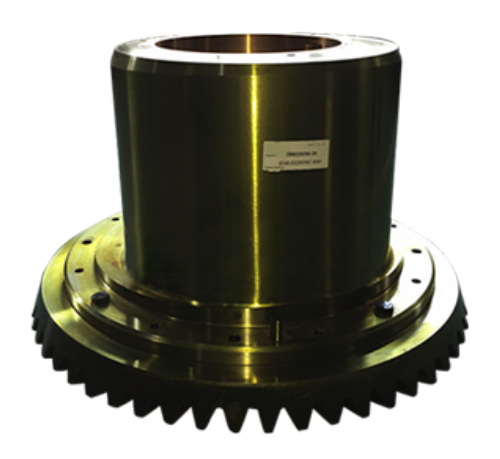

Gyratory Crusher Market Size In 2022 : SWOT Analysis, Growth

The Gyratory Crusher market has witnessed growth from Million USD to Multi million USD from to 2022. With the magnificent CAGR, this market is estimated to reach Multimillion USD in 2029.

Learn More

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing

Learn More

PDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

All crushers have a limited reduction ratio m eaning that size reduction will take place in stages. 3.2 Operation stages: The operating stages in minerals process ing have remained the same for

Learn More

Type of crushers and their difference - JXSC Mining

12/10 · Impact crushers and cone crushers tend to be used during these stages to better control particle size and shape. Understanding how to best match the type of crusher to the

Learn More

Aggregate Crushers, for Rock, Ore & Minerals - Gilson Co

The portable units perform well in crushing aggregates, minerals and ores, while the Holmes crushers are designed for crushing coal and coke. Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore, and can bridge the gap between laboratory and production outputs. Models with 3

Learn More

Selecting the right crusher for your operations - Quarry

Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form finished products down to 12mm or less. Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are

Learn More